Section Branding

Header Content

Factories, farms and flight: How Georgia could propel sustainable jet fuel into the future

Primary Content

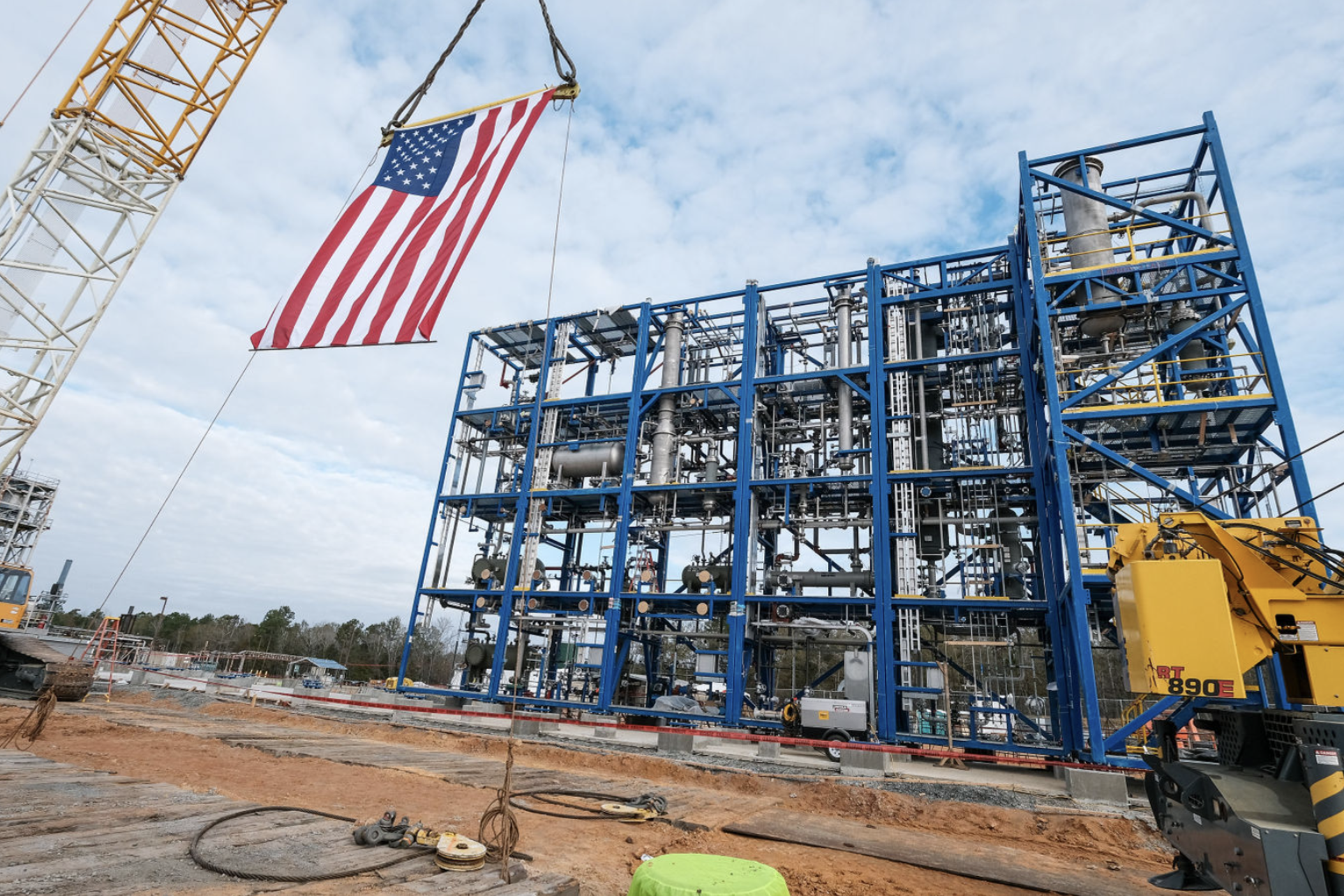

“So this is alcohol-to-jet technology,” refinery manager Nick Cavalier said as he walked along a gravel road through a construction site in Soperton, about halfway between Savannah and Macon.

He points to a factory — or rather, a future factory. It's still under construction, but inside the exposed framing, you can see big metal reactors.

“What these reactors do is, as you take in this ethanol, you start stacking the carbon chains,” Cavalier explained. “Jet fuel ranges anywhere from a C9 to a C18 carbon molecule.”

Working for the sustainability tech company LanzaJet, Cavalier has extensive experience in the energy sector and a deep understanding of the complicated science behind Freedom Pines Fuels in Soperton — the first commercially operated alcohol-to-jet fuel refinery in North America once it begins production later this year.

A simpler, more cinematic way of explaining alcohol-to-jet technology can be found in the iconic 1985 film Back to the Future — in particular, the final scene, in which a frantic Doc Brown rummages through a garbage can for some less-than-glamorous fuel.

“He was feeding banana peels and trash into the back of his DeLorean, and it was fueling it to fly,” Cavalier said. “At a real elementary level, that is what we're doing here: taking waste products, making ethanol out of it, that then turns into jet fuel to fly airplanes in the sky.”

This is just one method of making sustainable jet fuel in Georgia — a state with a major role to play in the decarbonization of aviation, being home to both the world's biggest airline by market capitalization and the world's busiest airport.

“Definitely, we can use a lot of crops,” said University of Georgia sustainability sciences professor Puneet Dwivedi, who co-authored a recent study on the hidden power of high-oil crops — in particular, one you've likely never heard of: carinata, also known as Ethiopian mustard.

“Carinata is a non-edible crop,” Dwivedi explained. “So, that helps because then the food-versus-fuel debate is out.”

In other words, converting carinata into jet fuel doesn't take away from the food supply, like using soybeans would. Plus, it's pest-resistant. Another benefit: Carinata is especially well-suited for Georgia's warm climate, as it would grow during the state's temperate, rainfall-rich winters.

“So, it is not competing with major cash crops that we have in the South — for example, cotton,” Dwivedi said.

However, he added that there's a big caveat: The USDA doesn't recognize carinata as a cover crop. As a result, many farmers hoping to grow carinata miss out on subsidies, and therefore take on significant financial risk.

Experts say this risk gets at a larger challenge facing sustainable jet fuel: There's not a lot of government money being thrown at it, despite a White House goal of producing 3 billion gallons annually by 2030.

“We have a long road ahead to decarbonize aviation fuel,” said Graham Noyes, who directs the nonprofit Low Carbon Fuels Coalition. “Most of the challenge is the cost gap. We have fossil fuels that have been subsidized for many, many years and have a very well-established infrastructure.”

Noyes said that although “great strides” have been made — such as enacting a tax credit for sustainable jet fuel producers in the Inflation Reduction Act — the federal government needs to mandate requirements by fuel producers of all stripes.

“Typically, a petroleum refiner or importer has to either sell less and less carbon-intensive fuel or buy credits in the marketplace to meet those requirements,” said Noyes, explaining how a so-called Clean Fuel Standard program is already employed by some state governments, including California, Oregon and Washington.

Those credits, he explained, create what is essentially “a new revenue stream” for low-carbon fuel producers like LanzaJet.

Back in Soperton, Nick Cavalier takes pride in the work he's doing now — a “legacy project,” as he calls it — after having spent most of his career in high greenhouse-gas industries.

“I have worked in traditional oil and gas for 24-and-a-half years, and I always thought it was really hard for me to explain to my family what I did for a living — how I made an impact and a difference in the world,” Cavalier said. “And here's a clear example where I could leverage a lifetime of experience to really, truly make an impact into something different and change the environment. And that's something that can be explained to my kids.”

Correction

The audio version of this story states that the Freedom Pines Fuels facility will be the first commercially operated sustainable jet fuel refinery in North America (which was according to LanzaJet via Cavalier). A later statement from a LanzaJet spokesperson clarified that it will be North America's first commercially operated sustainable jet fuel refinery to use alcohol-to-jet technology. The audio also states that the facility's walls have not yet been built. A later statement from a LanzaJet spokesperson clarified that the facility will not have walls.