KIA Motors Manufacturing Georgia

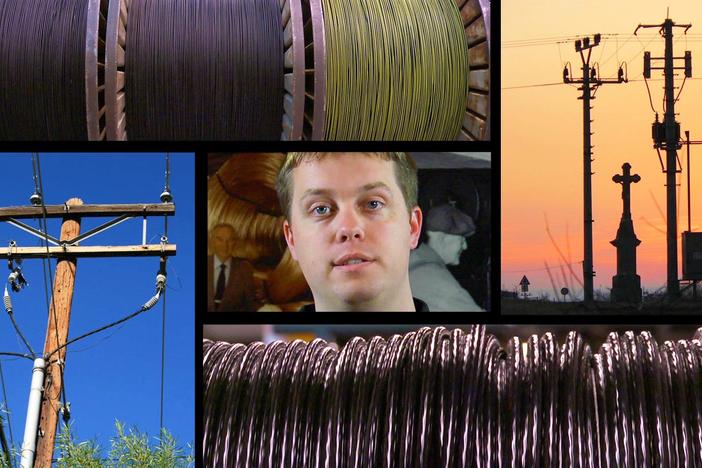

Fast Forward travels to the west side of the state to clear up some misconceptions about modern factories. We visit KIA Motors Manufacturing Georgia in West Point. This state-of-the-art facility rolls out one new car every minute, and we show the entire process—from steel coils all the way to the test track. And while we’re here, we learn who really runs the world (hint: it’s not the “cool kids”).

KIA Motors Manufacturing Georgia

Fast Forward travels to the west side of the state to clear up some misconceptions about modern factories. We visit KIA Motors Manufacturing Georgia in West Point. This state-of-the-art facility rolls out one new car every minute, and we show the entire process—from steel coils all the way to the test track. And while we’re here, we learn who really runs the world (hint: it’s not the “cool kids”).

Science

Plan and carry out an investigation on the effects of balanced and unbalanced forces on an object and communicate the results.

Ask questions to identify and explain the uses of simple machines (lever, pulley, wedge, inclined plane, wheel and axle, and screw) and how forces are changed when simple machines are used to complete tasks.

Construct an explanation about the importance of molecular-level structure in the functioning of designed materials.

Obtain, evaluate, and communicate information about how to refine the design of a chemical system by applying engineering principles to manipulate the factors that affect a chemical reaction.

Construct an explanation based on evidence using Newton's Laws of how forces affect the acceleration of a body.

- Explain and predict the motion of a body in absence of a force and when forces are applied using Newton's 1st Law (principle of inertia).

- Calculate the acceleration for an object using Newton's 2nd Law, including situations where multiple forces act together.

- Identify the pair of equal and opposite forces between two interacting bodies and relate their magnitudes and directions using Newton's 3rd Law.

Obtain, evaluate, and communicate information about the importance of conservation laws for mechanical energy and linear momentum in predicting the behavior of physical systems.

Use mathematics and computational thinking to identify the relationships between work, mechanical advantage, and simple machines.

Social Studies

Evaluate the economic impact of various industries in Georgia including agricultural, entertainment, manufacturing, service, and technology.

1. Increasingly, people are worried that robots will replace many of the jobs that humans do. But some economists think that as jobs go away, others will be created. What jobs might be created by the robots in the Kia factory?

2. Ergonomics deals with how a car feels to and is used by a human operator. Name something that you think is difficult to use in a car and maybe a solution to that problem. To help you work through the design process check out the NOVA series on PBSLerningMedia

Transmission: the part of a vehicle that uses the power produced by the engine to turn the wheels

Ergonomics: a science that deals with designing and arranging things so that people can use them easily and safely

Biomechanics: the research and analysis of the mechanics of living organisms

-

Special Thanks

Joanne Mabry, Shonna Cole, Randy Jackson, Jennifer Hardaway, James Watson, Herbert Henderson, Corinne Hodges

This content was developed under a grant from the U.S. Department of Education. However, this content does not necessarily represent the policy of the U.S. Department of Education, and you should not assume endorsement by the Federal Government.